Services

We provide engineering expertise, laboratory testing, on-site installation and fast turnaround services, all managed by experienced specialists from different disciplines.

Our team supports your GRP and composite projects through every phase of their lifecycle.

In collaboration with engineering partners, we also carry out stress and strength analyses using Rohr2 and Caesar II, including support design for complex pipe networks.

We prepare detailed 2D and 3D drawings using AutoCAD and Inventor and provide all required calculations for piping systems, tanks and equipment.

.jpg)

Technical support begins as early as the proposal stage. Our team offers input on feasibility and implementation and continues to assist throughout planning and execution.

With years of experience and ongoing development, Kurotec has established a trusted engineering department that works according to internationally recognised standards.

Engineering &

stress analysis

When time is critical… we’re here for you!

Project

management

Shutdown operations are, by nature, intense and time-sensitive tasks involving entire plant systems. For customers, partial plant shutdowns require significant planning efforts. These works often impact downstream processes and suppliers – and production downtime always carries a financial cost.

That’s where our project and installation management comes in. With a high degree of flexibility, we help ensure smooth execution. The calculation and production of required components follow a strict timeline, and installation must be perfectly coordinated – a service we are proud to offer.

We’re happy to share our references in our project list or in a personal conversation.

03 International experience

and flexible execution

Our installation teams work across Europe and beyond. All staff hold SCC and VCA safety certifications and are trained for complex industrial environments. Depending on your needs, we can assign a supervisor to support your team or provide a full crew including site managers, welders and laminators.

02 Reliable quality and tested safety

Following delivery, we perform professional installation and all necessary tests. These include leak tests, pressure tests and full system checks. Our goal is to deliver a system that works flawlessly, meets all relevant standards and offers long-term reliability. You define the scope. We deliver the result.

01 Complete support from

planning to commissioning

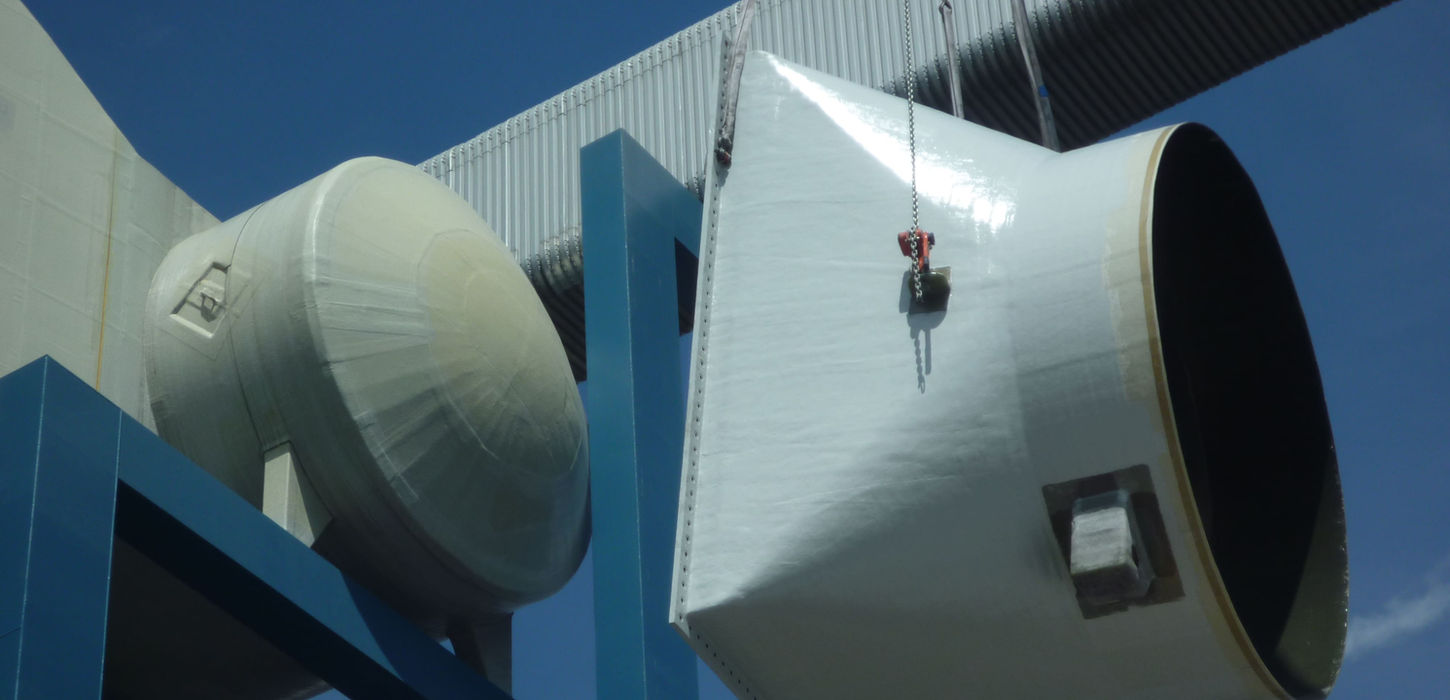

At Kurotec, installation means more than just assembly. We guide your project through every phase, starting with the initial idea and continuing through planning, production, delivery and final commissioning. Our goal is to provide a complete solution from a single source.

You define the scope. We deliver the result.

Installation

and service

The renovation and coating of tanks and special GRP components has been one of our key areas of expertise for many years. With deep technical knowledge and practical experience, we help restore your systems to their original reliability and longevity.

Coatings of tanks and GRP constructions

Depending on the damage identified, renovation can include:

Partial renewal of the chemical-resistant layer

Complete removal of the layer with subsequent inspection and repair of the structural laminate

Diagnostics and repair process

Shutdown operations are, by nature, intense and time-sensitive tasks involving entire plant systems. For customers, partial plant shutdowns require significant planning efforts. These works often impact downstream processes and suppliers – and production downtime always carries a financial cost.

Tailored renovation planning

Each project begins with a careful inspection of the damaged GRP element. Based on this analysis, we create a renovation plan that is tailored to your specific application. In our assessment, we consider:

- The properties of the medium in use

- The current surface condition

- A cost comparison between renovation and new construction